{Catering to strict criteria for subzero operations depends on expert valve technology. Our firm’s chill 3-way round apparatus products are engineered to provide robust operation even at sub-zero temperatures, typically below -150°C. These mechanisms offer notable conveyance control in chilled materials such as nitrogen, oxygen, and argon, frequently used in domains like LNG, academic equipment, and therapeutic facilities. The company specialize in strong construction, including minimal-friction barrier components and careful shaping, to warrant airtight working. Think about the gains of improving your frosty system with our state-of-the-art 3-way ball instrument offers.

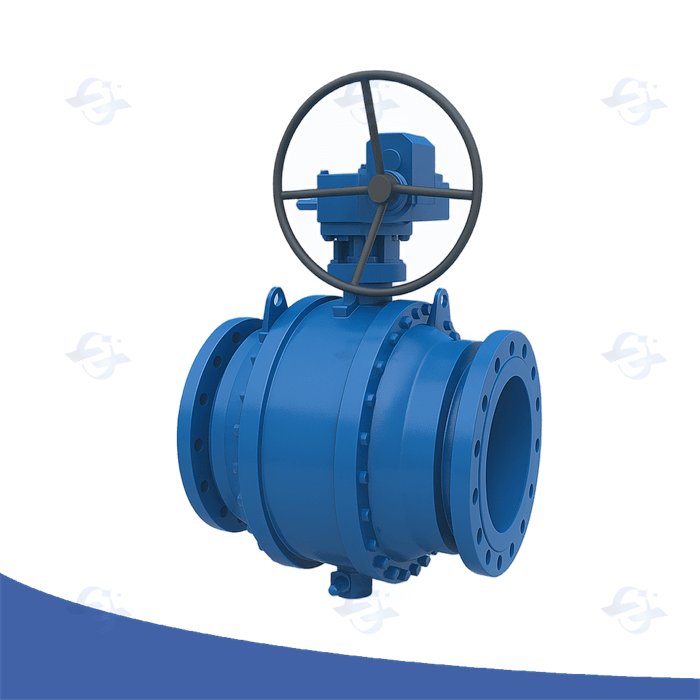

High-Performance Twin Seal and Vent Sphere Valve Units

For crucial applications, particularly where exfiltration is prohibited, premium double block and bleed valve systems offer extraordinary safety. This novel design incorporates two individual valve seals, besides a bleed opening, allowing for verification of the total shut-off and examination of any potential spill. Typically employed in energy operations, synthesis handling, and sub-zero locales, these devices considerably augment facility reliability and cut the hazard of ecological footprint.

Three-Channel Cryogenic Spherical Valve Construction

An creation of three-way frosty globular tap presents a special engineering issue. These components are usually employed in vital industrial uses where harsh temperatures must be upheld. Key elements include product determination, expressly regarding brittleness at lesser temperatures, and the necessity for close barrier to prevent escape of cold compounds. Intricate study styles and precise creating routines are indispensable to confirm steady operation and permanence under such strict running conditions.

Icy Actuator Performance in Manufacturing Applications

Our demanding specifications of subzero operations, such as refined natural petroleum handling and cryogenic nitrogen storage, necessitate trustworthy controller methods. Integral block vent instruments provide a particularly robust and effective approach to achieving zero-leak tightness while facilitating regular maintenance. Their design blends a primary valve with a small outlet corridor, allowing supervised pressure venting during termination and reengagement. This inherent trait minimizes persisting fluid entrapment, thereby ensuring excellent defense and competence even under the most tough employing cases. Furthermore, the power to oversight outflow transit provides valuable monitoring figures for procedure advancement.

Securing 3-Way Round Valve Closure in Extreme High-Pressure Scenarios

Obtaining trustworthy stopping performance with 3-way rotary valves becomes particularly significant when operating within considerable pressure locales. The design is obliged to account for significant strains and potential spillage pathways. Specialized compositions, often including state-of-the-art metals like durable steel or exotic alloys, are imperative to withhold the tough conditions. Furthermore, advanced interface geometries and exact creation processes are required to minimize creep and guarantee a sealed bond even under fluctuating strain cycles. Regular audit and routine preservation programs are too vital for persistence and continued operational functionality.

Cryogenic Ball Valve Leakage Prevention Strategies

Decreasing "discharge" from cryogenic "orbital valves" demands a multifaceted "tactic". Initial "layout" considerations are paramount; material "preference" must account for extreme "temperatures" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "assembly" processes – including stringent weld "reviews" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "key" component is proper "positioning"; thermal "diminution" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "supervision" for signs of wear and "restoration" of any identified issues – is indispensable for maintaining a reliable, leak-tight "seal”. Ultimately, a robust "schedule" incorporating these elements is necessary to ensure the safe and efficient "performance" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "threats", and costly "breakdown”.

Double-Layer Clamp and Release System Assessment Systems

To certify the integrity and safety of critical piping grids, rigorous twin block and exhaust tool examination systems are essential. These tests, often mandated by regulatory bodies and industry best methods, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the bleed apparatus remains functional and correctly discharges any trapped gas. A common system is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the seepage rate around the closed mechanisms is meticulously checked. The purge tool's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of evaluation results, including any anomalies observed, is necessary for maintaining a reliable procedure.

Analyzing Overall Block Bleed Instrument Effectiveness

For fully govern load apparatuses, a in-depth comprehension of integral block purge component capability is entirely paramount. These unique modules primarily serve to securely vent excess power from a installation during specific working periods. A usual positioning includes a sealed domain coupled to the central stress source, authorizing one guided venting whenever mandatory. The built-in plan lowers the threat of excess pressure, safeguarding both the equipment and the proximate environment. Regular inspection and preservation are mandatory to confirm maximal performance.

Identifying the Suitable 3-Way Ball Valve for Cryogenic Fluids

Determining a proper 3-tri-ball gate for cryogenic uses demands careful evaluation of several critical aspects. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present particular challenges. Material election is paramount; only materials with proven suitability and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized non-ferrous alloys, should be assessed. Furthermore, the instrument's sealing effectiveness is vital to prevent exfiltrations, requiring specialized stem sealing patterns and low-temperature substances. Finally, pressure ratings and actuation approaches, taking into account potential pressure jumps, must be attentively matched to the system's necessities. Neglecting these factors can lead to grave failure and safety jeopardies.

Chilled Rotary Valve Material Agreement Handbook

Choosing the appropriate constituent for cryogenic globular valves is paramount, given the harsh temperatures involved. This guide highlights common compounds and their functionality when exposed to cryogenic fluids such as solution nitrogen, coolant helium, and oxygen. Stainless steels, particularly grades 304 and 316, often demonstrate adequate resilience and oxidation resistance, though martensitic materials require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their bendability and resistance to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some plus points, may exhibit lessened capability at these low temperatures. Consultation with suppliers and comprehensive inspection is essential to verify lifespan and reliability in cryogenic tasks.

Increasing Dual Block and Bleed Setup Capability

Realizing optimal capability in double block and bleed applications hinges on a multifaceted strategy. Careful evaluation of device selection is paramount, with a focus on material accordance and impact determination. Regular monitoring of drain channels for obstruction is essential, often calling for the use of expert examination devices. Furthermore, methodology tuning—including scrutiny of circulation rates and load disparity—can substantially elevate overall configuration reliability and security. Finally, adherence to builder standards and the fulfillment of a solid upkeep schedule are critical for long-term stability and lifespan.

best cryogenic ball valves

best cryogenic ball valves