Within the challenging realm of building, capacity and accomplishment are key. To fulfill such demands, latest assembly apparatuses have developed to provide unrivaled functionality and robustness. Modern elite development apparatus packages are equipped with innovative technologies that maximize productivity while minimizing environmental impact. Extending over forceful diggers and conveyors to lithe jacks and petite instruments, these devices are engineered to manage the most intricate building endeavors effortlessly.

- Precision controls allow for smooth and precise performance, resulting in increased accuracy and reduced downtime.

- Heavy-duty construction ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Concrete Batching Plants: Designed for Optimal Output

Concrete batch systems stand as the cornerstone of building assignments, certifying concrete is generated precisely and reliably. These intricate designs apply numerous contemporary elements to elevate output within the concrete construction process. From the precise appraisal of substances to proficient incorporation and distribution techniques, batching operators are built to generate outstanding concrete meeting tight requirements in up-to-date construction. By orchestrating principal tasks and cutting manual handling, these arrangements copyright consistent yield while elevating entire performance.Stabilized Soil Mixing Plants Delivering Durable Foundations

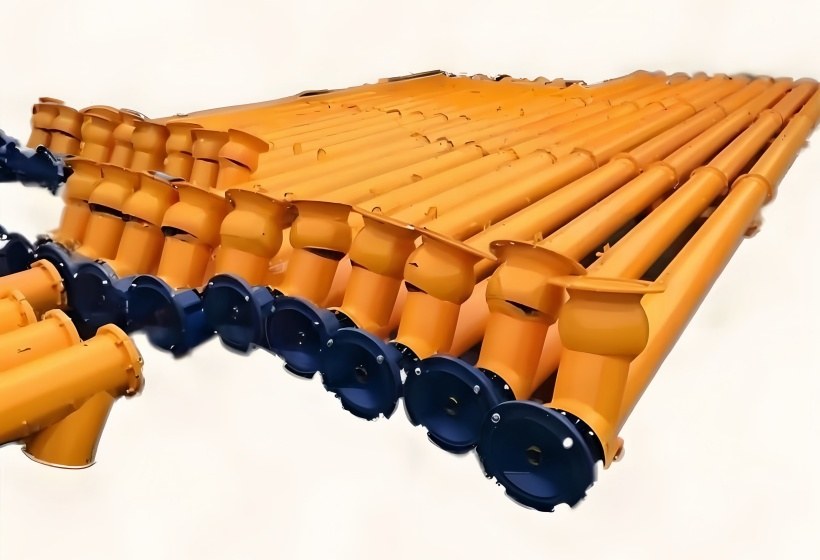

Within the universe of creation, resilience is critical. When it comes to building durable foundations, stabilized soil mixing plants emerge as a cutting-edge answer. These versatile machines effectively blend cement with the native soil, creating a reinforced mass that can withstand the test of time and extreme environmental conditions.

Providing exceptional durability and lifespan, stabilized soil mixers play a vital role across diverse ventures, spanning highways, overpasses, walkways, and civil/industrial buildings. By making use of the basic qualities of soil, these units offer an environmentally sound process for base formation.

Cement Facility Options for Each Venture

We grasp each fabrication assignment is exclusive and demands adapted cement formulas. For this reason, we extend multiple adjustable concrete manufacturing options suiting your distinct preferences. Be it a substantial commercial venture or a minor regional task, our proficiency and apparatus ensure premium concrete reliably. Our group of experts collaborates with clients to develop cement facility setups maximizing productivity, minimizing scrap, and producing outstanding outcomes. Our range covers concrete batching units, combination equipment, material management tools, pump systems, and control interfaces. Our devotion to patron fulfillment is persistent. We guarantee full support from early consultation to execution and sustained maintenance. Let us help you build success, one concrete project at a time.Mobile Batching Plants: Dynamic and Versatile

In the infrastructure field, effectiveness and flexibility are crucial. Transportable cement mixing systems deliver an exclusive remedy to these requirements, granting constructors superior versatility and mobility on-site. Deviating from permanent classic plants, these systems are conveniently relocated among projects, removing pricey and lengthy installation and removal procedures. This advances seamless operations, lower delivery intervals, and significant economic benefits.

The mobility of portable cement batching units creates numerous opportunities for builders. They facilitate productive backing for assignments in secluded spots, cramped urban environments, or wherever conventional plants cannot operate. Additionally, the ability to quickly relocate plants between jobs allows contractors to maximize their resources and minimize downtime.

- Improved Yield: Minimize travel time and get projects moving faster with on-site mixing.

- Lesser Financial Burden: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Boosted Elasticity: Tackle a wider range of projects in diverse locations.

Boasting their condensed form and durable functionality, movable concrete production systems change the infrastructure field. They supply constructors with instruments required to execute assignments effectively, affordably, and with steady exactness.

Exact Concrete Fabrication Using Modern Innovations

Contemporary concrete manufacturing experiences a significant transformation due to adoption of cutting-edge systems. Robotic technologies get utilized to reach unmatched accuracy throughout each phase, spanning from ingredient batching to ultimate delivery. This results in concrete with enhanced performance, reducing waste and optimizing resource utilization. Sensors play a crucial role in collecting real-time information about various parameters during production. This data is then analyzed to identify areas for improvement, enabling manufacturers to constantly refine their processes and deliver consistently high-quality concrete. Perks of high-accuracy concrete creation exceed the production operation solely. Improved characteristics of this cutting-edge concrete lead to tougher edifices, decreasing repair costs and lengthening structure lifespans.Fostering an Environmentally Responsible Future via Modern Construction Devices

The creation sphere faces a significant alteration, instigated by the pressing responsibility to cut its ecological impact. Advanced building machinery contributes importantly to this movement towards eco-friendliness. Power-supplied instruments are gaining popularity, decreasing exhaust and noise interference. What's more, evolution in machinery leads to improved devices that consume supplies thoughtfully. This progress not only benefits the environment but also boosts operational efficiency for construction companies.

The integration of green strategies in the infrastructure field is vital for securing a sustainable world. With the adoption of state-of-the-art devices and approaches, the industry assists in safeguarding nature for posterity.

The Key Associate in Building Ventures: Resilient Equipment, Knowledgeable Aid

For erecting next-generation infrastructure, steadfast associates are important. We deliver that assistance. Our selection includes powerful durable tools crafted to overcome demanding tasks. Our instruments integrate advanced systems offering excellent efficiency and output.

Nevertheless, we serve beyond basic device distributors. Our group of seasoned experts delivers exceptional assistance throughout the process. From analysis to servicing, we aid you in improving your development efforts.

- Our services include in-depth education sessions to prepare your crew for secure and efficient equipment use

- Also, we grant immediate professional service to respond to your problems and questions competently

- Our pledge centers on furnishing implements and experience essential to fulfill your development targets

Massive Concrete Manufacturing

Extensive building ventures require cement methods capable of enduring significant force and strain. Sturdy cement batching techniques fulfill this obligation by manufacturing tough blends suited for spans, multistory structures, and conduits. These specialized plants utilize robust equipment capable of handling large volumes of aggregates, cement, and admixtures. Exact determinations secure steady excellence and conformity with strict building requirements

- Upgraded supervisory units boost mixing fidelity and operational output

- Employing superior binders enhances the toughness of the mixture

- Durable concrete manufacturing plants serve important functions in development progress shaping daily environments

Streamlining Building Operations: Effective Concrete Processing and Transport

In the fast-paced world of construction, efficiency is paramount. A necessary aspect for attainment requires advancing your combination and shipment processes. By following established protocols, you should appreciably reduce refuse, lower charges, and upgrade comprehensive productivity. A significant aspect is deciding on adequate fusion tools for your individual preferences. Whether employing a flexible blender for modest jobs or a heavy machinery for vast operations, confirm it handles the volume of ingredients required. Furthermore, optimize your delivery routes to minimize travel time and fuel consumption.

- Implementing a system for tracking material usage can help in identifying areas where efficiencies can be made

- Systematic inspection of your amalgamation and delivery systems is important to copyright maximum operation and longevity

Comprehensive Concrete Building Methods

Across the area of fabrication, concrete operates as a support of sturdiness and permanence. Affording holistic support across all phases of your cement task is our motivation. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,

Inside the exacting universe of erection, operation and delivery are crucial. To comply with these expectations, current fabrication devices have improved to provide unequaled operation and consistency. Modern elite development apparatus packages are equipped with state-of-the-art mechanisms improving performance and lowering ecological damage. Including strong earth-movers and transporters to flexible hoists and miniaturized devices, these tools are crafted to tackle the most complicated infrastructure tasks smoothly.

- Advanced hydraulics allow for smooth and precise execution, resulting in increased accuracy and reduced downtime.

- Robust materials ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Batch Plants for Concrete: Tailored for Effectiveness

Concrete batch operators perform as the integral drivers of assembly projects, maintaining concrete is composed precisely and consistently. These intricate designs apply numerous contemporary elements to elevate output within the concrete construction process. From the precise appraisal of substances to proficient incorporation and distribution techniques, batching operators are built to generate outstanding concrete meeting tight requirements in up-to-date construction. By facilitating important activities and curbing hands-on participation, these frameworks secure dependable yield while advancing broad productivity.Stabilized Soil Plant Mixers Delivering Durable Foundations

Throughout the environment of erection, durability is indispensable. When it comes to building durable foundations, stabilized soil mixing plants emerge as a advanced remedy. These versatile machines powerfully mix binding compounds into indigenous ground, producing an augmented structure resilient to severe weather and temporal challenges.

Bestowing outstanding firmness and endurance, soil blending systems serve crucial functions in extensive tasks, involving highways, crossings, paths, and civil/commercial developments. By exploiting the native properties of terrain, these systems present a green strategy for groundwork assembly.

Concrete Production Plants for Various Jobs

We grasp each fabrication assignment is exclusive and demands adapted cement formulas. Thus, we grant assorted modifiable building material plant opportunities satisfying Concrete mixing plant for sale your specialized prerequisites. Whether executing a large-scale infrastructural plan or a tiny localized endeavor, our know-how and tools furnish high-grade concrete consistently. Our group of experts collaborates with clients to develop cement facility setups maximizing productivity, minimizing scrap, and producing outstanding outcomes. We offer a variety of components, including batching systems, mixing units, aggregate handling equipment, concrete pumps, control and monitoring systems. Our allegiance to user satisfaction is unwavering. We ensure robust aid from initial planning to implementation and routine care. Depend on us to boost your success, step by step.The Power of Mobile Concrete Mixing Plants

Amid the creation sphere, capability and elasticity are critical. Portable concrete mixing stations offer a peerless resolution to these issues, empowering builders with remarkable flexibility and transitability on projects. Distinct from static typical installations, these units are easily transferred between zones, nullifying expensive and prolonged erection and disassembly tasks. That fosters coordinated tasks, curtailed durations, and considerable fiscal advantages.

The mobility of portable cement batching units creates numerous opportunities for builders. They allow competent servicing of ventures in remote places, narrow city settings, or wherever permanent facilities are unworkable. What's more, the ability to rapidly transport plants among tasks allows contractors to boost resource use and curtail idle times.

- Augmented Throughput: Minimize travel time and get projects moving faster with on-site mixing.

- Minimized Expenditures: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Improved Flexibility: Tackle a wider range of projects in diverse locations.

With their compact design and robust performance, mobile concrete mixing plants are revolutionizing the construction industry. They equip builders with resources necessary to complete tasks productively, economically, and with consistent accuracy.

Pinpoint Concrete Production through Innovative Solutions

Recent concrete generation encounters a meaningful alteration facilitated by leading technologies. Electronic regulation is employed to attain superior exactitude through every portion, from initial batching to final provision. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Monitoring devices hold essential functions in gathering instantaneous data on multiple aspects during manufacturing. Compiled information is analyzed to discover options for upgrades, supporting fabricators to continuously perfect procedures and supply uniformly superior concrete. Assets of meticulous concrete manufacturing extend past the assembly process exclusively. Improved characteristics of this cutting-edge concrete lead to tougher edifices, decreasing repair costs and lengthening structure lifespans.Fostering an Environmentally Responsible Future via Modern Construction Devices

The erection space experiences a profound metamorphosis, spurred by the urgent call to diminish its environmental disruption. Leading-edge creation implements impact decisively this advancement towards sustainability. Electric-powered machines are becoming increasingly commonplace, reducing emissions and noise pollution. Furthermore, advancements in design are leading to more efficient equipment that consumes resources more wisely. This progress not only benefits the environment but also boosts operational efficiency for construction companies.

The adoption of sustainable practices in the construction sector is essential for creating a livable future. By embracing innovative equipment and technologies, the industry can contribute in protecting our planet for generations to come.

The Key Associate in Building Ventures: Resilient Equipment, Knowledgeable Aid

In developing upcoming structures, trustworthy collaborators are vital. We supply that backing. Our selection includes powerful durable tools crafted to overcome demanding tasks. Our instruments integrate advanced systems offering excellent efficiency and output.

Yet, we act as more than simple tool vendors. Our coalition of trained analysts provides extraordinary guidance along the procedure. From planning to repair, we assist you in maximizing your building endeavors.

- Our support involves elaborate learning initiatives to make your team competent in secure and efficient tool use

- We provide on-site technical support to address any questions or concerns you may have

- Our focus emphasizes supplying equipment and skills crucial to accomplish your construction aims

Large-Scale Concrete Production

Broad assembly operations demand concrete techniques prepared to handle intense strain and force. Resilient cement batching technologies tackle this issue by producing strong blends intended for overpasses, high-rises, and underground passages. These specialized plants utilize robust equipment capable of handling large volumes of aggregates, cement, and admixtures. Precise measurements ensure consistent quality and compliance with stringent building codes

- Improved oversight technologies increase batching precision and performance

- Adopting advanced binders fortifies the durability of the substance

- Resilient batching systems provide critical support for erection advancement impacting habitual activities

Streamlining Building Operations: Effective Concrete Processing and Transport

Within the hurried realm of erection, functionality is indispensable. A crucial component to realize this includes refining your combination and logistics procedures. By utilizing effective strategies, you will noticeably minimize leftovers, reduce outlays, and boost comprehensive performance. A vital component consists of selecting compatible mixing technology for your exclusive criteria. Be it a transportable mixer for small undertakings or a sturdy unit for major projects, ensure it accommodates the amount of materials necessary. What's more, adjust your shipment paths to shorten travel periods and fuel usage.

- Adopting a method to monitor resource consumption assists in pinpointing opportunities for improvements

- Periodic repair of your fusion and logistics apparatus is indispensable to secure prime performance and lifespan

Concrete Services Throughout the Project

Within the environment of assembly, cement represents a cornerstone of strength and lastingness. Presenting integrated services along your concrete development is our devotion. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,