professional mailing carton fabricator why rely on innovative cardboard carton fabricators for versatile packaging needs?

Analyze the comprehensive field of corrugated packaging manufacturing through this complete overview. This presentation reveals the vital processes for changing plain sheets into robust containers that cover products during shipment. Spanning corrugation, design, and completion, we shed light on the nuances of this crucial market.

- Investigate the different sorts of corrugated parcels and their specialized roles.

- Review new breakthroughs in packaging production.

- Examine the sustainability issues and renewable solutions.

Whether being an academic, specialist, or field admirer, this overview imparts relevant facts on the transforming packaging market.

Creating Innovations from Corrugated Sheets

Corrugated pulpboard, mostly neglected as simple shipping product, provides a diverse crafting resource. Its rugged nature allows the creation of unique structures and designs, spanning useful organizers to fanciful embellishments. By applying originality, it is possible to adapt this standard medium into anything spectacular.

Examine the wide-ranging options in corrugated pulpboard crafting through:

- Exploring numerous methods like clipping, folding, and stacking

- Using recycled content for an environmentally sound method

- Unveiling your art to excite others

Due to its low cost, availability, and adaptability, corrugated fiberboard suits hobbyists at every age and ability level. Tap into your artistic side and allow your innovation to soar using this modest material.

The Science and Art of Corrugated Packaging Design

Corrugated box production portrays a thrilling synthesis of technical knowledge and creative design. It rises above standard making; it emphasizes developing a protective case that shields goods throughout delivery while also making a enduring mark on patrons.

A knowledgeable developer perceives the subtle traits of corrugated board, refining its gauge, flute form, and organization to accommodate special criteria of each unit.

- Also, stylistic aspects matter greatly.

- A precisely crafted carton is clearly apparent in stores, enticing the focus of future clients.

- Chiefly, packaging formation harmonizes safety and aesthetic.

Fulfilling Orders: Boosting Your Container Manufacturing

With successful operations and escalating orders, it's imperative to maintain capacity for addressing client demands. Increasing carton output may unlock smooth workflows and solidify trustworthy standing.

Primarily, analyze your production processes. Inspect installed devices and labor to discover probable obstacles or regions for advancement. Thereafter, examine alternatives for expanding output capacity. Weigh acquiring new gadgets or optimizing existing systems to heighten capacity.

Understand that expanding numbers is less vital than perfecting total workflow. Incorporate effective manufacturing practices to decrease refuse and enhance input utilization. Streamline workflows, automate repetitive tasks, and invest in employee training to create a high-performing team.

Eventually, strengthen enduring relationships with purveyors to copyright stable supply lines. Implementing these steps, you will productively advance packaging manufacturing and fulfill expanding buyer desires.

Breakthroughs in Corrugated Solutions

The carton field ceaselessly develops, fueled by requirements for renewable, efficient, and inventive methods. Corrugated fiberboard, a dependable substance for years, undergoes revival driven by revolutionary inventions. From resilient forms to automated traits, corrugated packaging board welcomes innovation. Suppliers develop original plans to upgrade carton performance, adopting eco-conscious materials and systems. The result is a wave of novel packaging solutions reshaping the industry landscape.

These modernizations overcome vital troubles impacting businesses, including reducing discard and upgrading distribution. Buyers equally profit from these innovations, receiving packaging that is stronger and easier to use. The scenario for corrugated materials is bright, full of opportunities to advance eco-conscious and effective packaging environments.

Eco-Friendly Corrugated Packaging: Responsible Decisions

Corrugated shipments maintain a significant position in current delivery frameworks. Traditionally made from paper, these containers have a significant impact on the environment. However, increasing consciousness regarding eco-friendly methods applies equally to manufacturing carton goods. Fortunately, creative methods exist to enhance the environmental friendliness of such boxes.

An essential characteristic includes employing repurposed board. Through employing manufacturing or consumer leftovers, the need for fresh resources decreases, preserving woodlands and natural assets.

Similarly, constructors focus on green manufacturing protocols. The initiatives involve boosting energy efficiency and lessening leftovers in transport systems. Clients might help by preferring parcels confirmed as green. Seek certifications like Forest Stewardship Council or Sustainable Forestry Initiative, ensuring ethical procurement and production.

Via embracing these measures, we sustain cartons as vital market players while reducing ecological footprint.

Maintaining Superiority in Cardboard Packaging

Realizing top-tier output in container manufacturing involves strict quality supervision. Beginning with material acquisition and ending with product evaluation, all stages need constant vigilance. Exacting rules guide all processes to ascertain each case complies with leading parameters.

- Inspecting raw materials for defects, strength, and uniformity is crucial to preventing potential problems down the line.

- Following exact scales and margins during cutting and bending confirms boxes are mechanically strong and compatible for use.

- Systematic examination of printing performance guarantees brilliant visuals and clear typography

- Incorporating digital quality monitoring tools improves performance and precision in inspection functions

By prioritizing quality control at every stage, manufacturers can deliver corrugated boxes that are both durable and visually appealing. This dedication to excellence not only satisfies customer expectations but also strengthens the brand's reputation in the market.

Carton Labeling: Presence and Outcome

Container label printing serves as a crucial element of brand identity. When buyers view your goods, the packaging acts as a key tool for leaving an impact. A well-designed print on a corrugated box can engage attention, communicate your brand's identity, and ultimately influence purchasing decisions.

Besides, packaging branding furnishes numerous ways to customize your shipments. By means of striking pigments to original graphics, you can demonstrate brand personality through carton design.

In conclusion, carton printing transcends basic utility – it is an effective tool to build brand image and engage your market.

From Raw Elements to Finished Goods: The Corrugated Carton Workflow

The production of packaging is a captivating method that changes simple supplies into a crucial transport and protection tool. It originates by collecting pulp, commonly obtained from reclaimed resources. This pulp is then transformed into sheets of corrugated board, featuring a fluted center layer sandwiched between two flat linerboard layers.

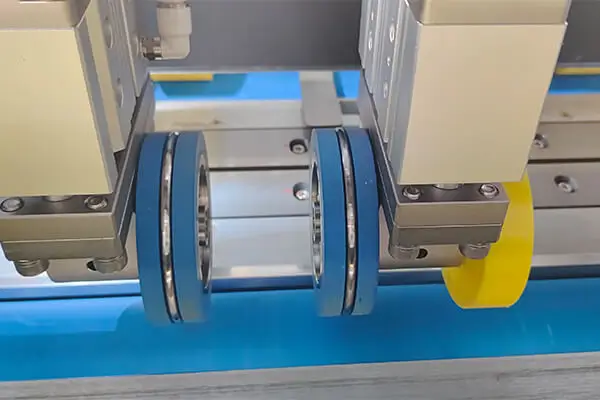

These boards are accurately sliced to specific parameters, then combined with expert machinery to produce the targeted package design. Resins assist importantly in connecting segments solidly, assuring a powerful and long-lasting formation.

Lastly, shipments receive meticulous examination steps to affirm toughness and compliance with commercial standards.

Emerging from simple bases, the case unfolds as a multifunctional packaging wonder, capable of shielding assorted products in transit.

Worldwide Box Business: Directions and Possibilities

The international packaging sector witnesses a stage of development. corrugated box maker This dynamic sector is fueled by rising consumer demand for packaging. Principal factors involve surge of electronic commerce and demand for sustainable packages