Engine producers demand the highest measures of precision in pieces. A critical aspect is achieving a perfect polishing on sunken sections, which can be arduous with traditional means. Our cutting-edge Precision Dished EndAC Polishing Machine addresses this need by yielding an intelligent and pinpoint method. This gadget applies bespoke tooling and a directed polishing method to obtain a smooth film on sunken sections, securing optimal functionality and hardiness of automotive units.

- The instrument’s programmable systems allow for precise corrections to the polishing conditions, guaranteeing coherence and echoing.

- Its small architecture optimizes workspace output while limiting operator stress.

- Combination with existing manufacturing operations is seamless, optimizing production workflows.

Efficient Tank Polishing Machines for Stainless Steel Fabrication

In the sphere of stainless steel production, realizing a flawless and brilliant texture is paramount. To complete this endeavor, high-efficiency tank polishing machines have appeared as critical apparatuses. These high-tech machines leverage cutting-edge technology to precisely clear surface roughness and improve a polished sheen on stainless steel tanks.

- Moreover, high-efficiency tank polishing machines are crafted for optimal performance, including durable construction, sturdy motors, and creative polishing heads that cut down surface damage.

- Thereupon, fabricators can realize exceptional results with minimal effort, facilitating their production methods and yielding high-quality tanks that address the stringent expectations of various realms.

Progressive Cylindrical Polishing System for Precision Engineering

The desire for exceptional surface level in precision engineering is constantly rising. To fulfill these rigorous needs, a innovative cylindrical polishing system has been created. This advanced instrument harnesses cutting-edge procedures to achieve unparalleled surface polish. It competently reduces imperfections and enhances the overall capability of cylindrical modules across a wide range of branches.

- Gains include increased output, reduced manufacturing budgets, and improved product durability.

- The system is engineered to handle a multifaceted range of components, including metals, ceramics, and plastics.

- Operators can easily tweak the polishing specifications to obtain the desired coating.

This advanced cylindrical polishing system represents a significant leap forward in precision engineering, supporting manufacturers to produce parts of exceptional excellence and output.

State-of-the-art CNC Polishing Solutions for Complex Shapes

Producing a perfect appearance on intricate designs can be a demanding task. Traditional polishing methods often struggle to yield consistent results on complex patterns, leading to time-consuming processes. However, the advent of robotic CNC polishing solutions has innovated the industry, permitting manufacturers to achieve unprecedented standards of accuracy and efficiency.

These innovative systems exploit smart machining technology to finely hone surfaces with minimal operator intervention. Equipped with high-speed spindles and a variety of polishing tools, CNC machines can readily handle even the most demanding profiles.

Additionally, these solutions offer optimized control over variables such as pressure, speed, and tool path, promoting consistent results across different materials and complexities.

- Pros of automated CNC polishing include:

- Improved precision and surface caliber

- Cut cycle times and production costs

- Enhanced product consistency and repeatability

- Improved design flexibility for complex shapes

Rugged Tank Polishing Machine for Industrial Applications

For demanding industrial conditions where performance is critical, a heavy-duty tank polishing machine is an important tool. These machines are specifically crafted to handle the burdens of regular operation in harsh environments. Equipped with durable construction and high-torque motors, they can effectively clean rust, paint, and various contaminants from tank surfaces, conferring a smooth and sanitary finish. A variety of devices are available to accommodate different tank sizes and profiles, making them versatile for a wide range of applications.

Dished End Polishing Solution with Adaptive Control

Our leading Dished End Polisher utilizes intuitive Adaptive Control Technology to deliver unparalleled output. This innovation continuously controls the polishing process in real time, assuring optimal surface grade for a wide range of products. The Adaptive Control Technology refines the adjustment of key variables, such as pressure, speed, and oscillation, to achieve steady results every time.

- Advantages include:

- Augmented surface finish quality

- Reduced polishing time

- Improved control over the polishing process

- Versatility for a range of materials and applications

Automated Polishing System for Precise Surface Preparation

A CNC polishing apparatus is a state-of-the-art tool used in various markets for producing high-quality surface finishes. These machines utilize computer numerical control (CNC) technology to meticulously polish surfaces, wiping out imperfections and establishing a smooth, refined appearance. The heavy-duty design of CNC polishing machines allows for mass manufacturing.

- Fabrication environments

- Non-metals

- Achieving desired textures

The high-tech nature of CNC polishing machines delivers steady results, decreasing human error and enhancing efficiency. By leveraging a variety of finishing tools, these machines can process a diverse selection of surface types and resources.

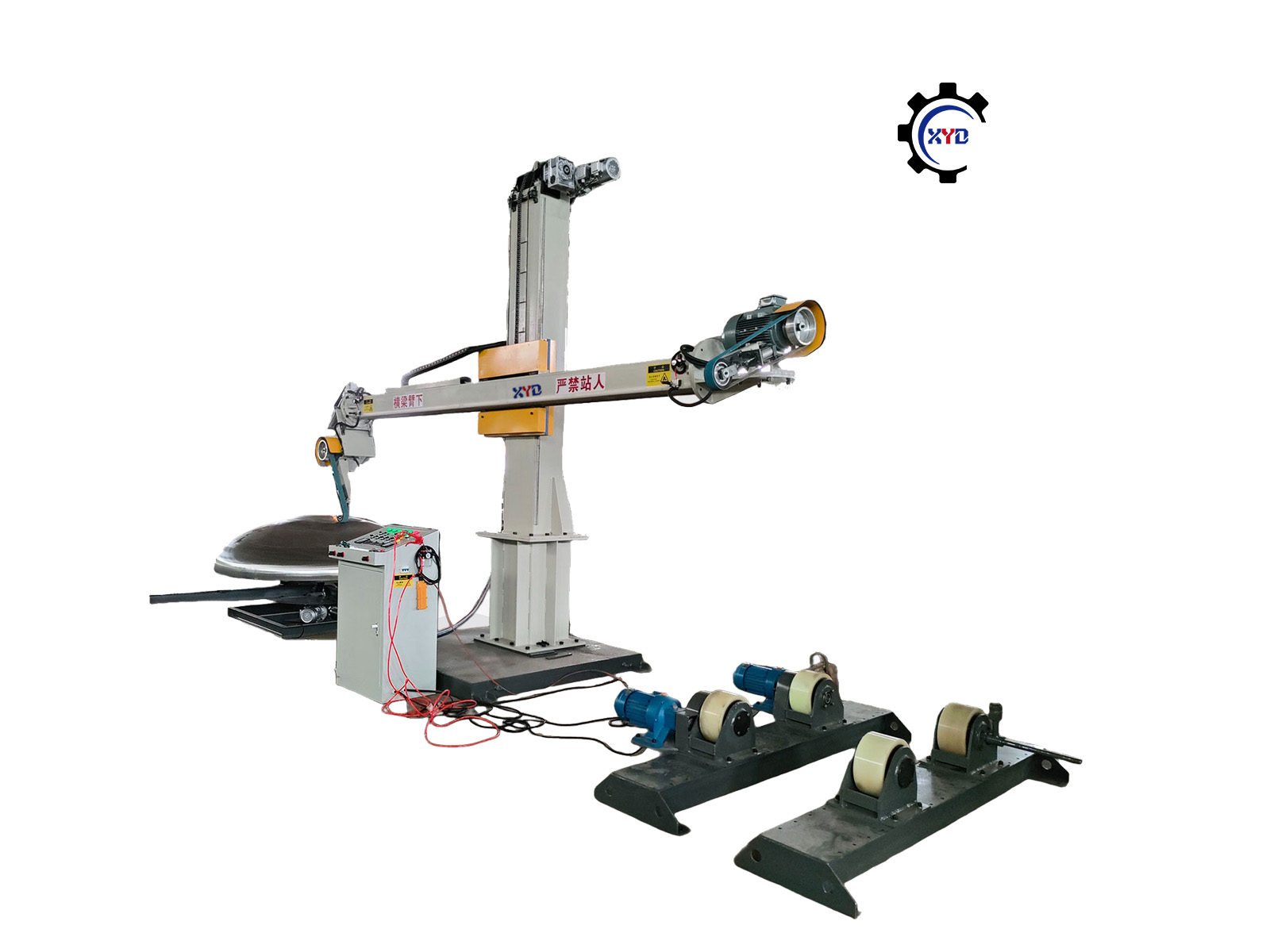

Cylindrical Polishing Equipment for Large Diameter Workpieces

Constructing and refining large diameter cylindrical objects often depends on specialized equipment. These machines are built to secure precise specifications on objects with significant girth, employing a variety of surface enhancers.

The choice of cylindrical polishing equipment is shaped by the specific material and desired outcome. Some common types include horizontal lathes, each offering distinct advantages for enhancing appearance.

- needs expectations requirements demands

- Holding equipment are essential to securely hold large diameter pieces throughout the processing process.

- Precise control of rotating speed and abrasive application are critical for securing consistent results.

Turbocharged Dished End Polishing Machine for Mass Production

In today's speedily transforming manufacturing industry, the requirement for high-performance high-volume production programs is essential. To cope with this task, manufacturers are integrating cutting-edge technologies like high-speed dished end polishing machines. These sophisticated devices deliver exceptional exactness in a time-sensitive manner, maintaining consistent quality and first-class surface finishes for a inclusive range of components.

Designed to handle large production runs with remarkable speed, these machines utilize advanced polishing techniques to achieve a finish required for demanding applications. Key features include high-speed spindles, intelligent control systems, and innovative sheening pads that work in synergy to maximize results.

Over and above, these machines often incorporate automation tools for increased yield and reduced labor costs. This combination of speed, accuracy, and mechanization makes high-speed dished end polishing machines a vital asset for manufacturers attempting to elevate their production processes and accommodate the growing requests of the market.

Acute CNC Polishing for Aerospace and Diagnostic Devices

In the complex fields of aerospace and medical device fabrication, surface quality is fundamental. CNC polishing supplies a highly precise and solid method to realize the exacting finishes required for these critical applications. By exploiting advanced CNC machining technology, manufacturers can create surfaces with exceptional refinement, detail, and endurance. This process enables the production of components that conform to stringent standards for capability, reliability, and security.

- criteria needs expectations preferences cnc polishing machine expectations

- Additionally, CNC polishing optimizes the rusting resistance and biocompatibility of items used in aerospace and medical devices.

- As a result, it plays a vital role in extending the lifespan and enhancing the effectiveness of these products.

Interchangeable Cylindrical Polishing System for Customization

Unveiling a revolutionary solution to cylindrical polishing: the Modular Cylindrical Polishing System. This innovative system facilitates unparalleled customization, fine-tuning to your specific conditions. With its interchangeable design, you can swiftly adjust the polishing heads, materials, and parameters to reach the desired finish for your cylindrical objects.

- expectations criteria conditions